Click this messge to hide it.

- Individually made to order

- Gable wall any width up to 19'8" or 6.0m - you just pay for the next size up, prices are in 20" or 500mm increments

- Side wall any length up to 19'8" or 6.0m or longer - you just pay for the next size up, prices are in 20" or 500mm increments

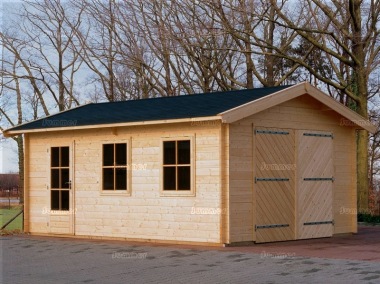

- Single garages: 3.0m, 3.5m, 4.0m, 4.5m and 5.0m wide garages (9'10" to 16'5") include 1 pair of double hinged doors

- Double garages: 5.5m and 6.0m wide garages (18'1" and 19'8") include 2 pairs of double hinged doors

- Double doors are joinery made with fully profiled timbers and morticed and tenoned joints throughout

- Double hinged doors include 19mm tongued and grooved boards and a mortice lock

- Double door width 7'6" (2290mm)

- Double door height 6'7" (2000mm)

- All timber used in the construction of this log garage originates from sustainable forests

- As with most log garages, the roof is supplied unassembled with the rafters and roof boards cut to size

- These log garages are untreated as standard

- 45mm or 70mm thick tongued and grooved wall logs

- Foundation beams for 45mm log cabins ex 3"x3" (70mm x70mm) pressure treated (lifetime preservative treatment)

- Foundation beams for 70mm log cabins ex 4"x3" (90mm x70mm) pressure treated (lifetime preservative treatment)

- 19mm thick tongued and grooved roof boards (finished size after machining)

- Decorative mineral felt tiles in a choice of colours included as standard

- Weatherproof L-shaped double fascia boards to front and rear

- Eaves height 2.25m (7'5")

- Ridge height varies according to width of garage

- Ridge height 3.0m or 9'10" (4.0m or 13'1" wide garages)

- External roof overhang approximately 12" to all sides (300mm)

- External garage width (gable wall) - priced up to 3.0m (9'10"), 3.5m (11'6"), 4.0m (13'1"), 4.5m (14'9"), 5.0m (16'5"), 5.5m (18'1") or 6.0m (19'8")

- External garage length (side wall) - priced up to 4.0m (13'1"), 4.5m (14'9"), 5.0m (16'5"), 5.5m (18'1") or 6.0m

- External garage sizes do not include the interlocking log corners

- Internal garage sizes - subtract 90mm if the logs are 45mm thick, subtract 140mm if the logs are 70mm thick

- This building is easy to deliver if access is restricted - all sections will pass through a normal single door

LOG CABINS - THE BENEFITS: Log cabins are popular for many reasons, especially as a comfortable garden room to sit and relax in but also as a workshop or heavy duty storage shed. On the outside cabins have a chunky look and feel. On the inside, with no internal framework, the clean lines look smarter than the inside of a traditional shed or summerhouse. In addition, the wall logs are thicker than the shiplap cladding used in traditional sheds and summerhouses, which provides better insulation. If you want the option of winter use we recommend floor and roof insulation, which is difficult to fit retrospectively so it needs to be fitted with the cabin. We offer low price insulation packs complete with fixings and instructions. Where available, double glazing also improves the insulation especially if the cabin has a large glazed area. Another significant benefit of log cabins is that you get more wood for your money when compared with a traditional shed or summerhouse or garden office. With no prefabricated wall panels a log cabin requires less production time.

NORDIC SPRUCE: This building is manufactured from 100% Nordic Spruce, the best quality timber used in log cabin construction. Nordic Spruce is grown primarily in the well managed forests of Scandinavia, Siberia and the coldest parts of Northern Europe. The cold climate ensures slow growth. The growth rings are much closer together than trees grown in warmer climates. As a result the timber is heavy and durable with a dense grain pattern. These forests are expertly managed on a sustainable basis so Nordic Spruce is an enviromentally friendly choice.

NATURAL WOOD: First, high grade timber is dried in kilns until it reaches the optimum moisture content, then it is planed smooth and machined into tongued and grooved logs and boards. Next the logs are precisely machined at the ends to ensure a precise fit. Finally, each cabin is carefully packed and wrapped. When you unwrap it the wood is untreated. We recommend treating it only after the cabin has been successfully installed and ideally within a week or two. Treating the logs before fitting may cause the wood to swell up and the logs may not fit together correctly. If you are fitting your cabin in a restricted space where future access will be difficult you can stain the logs during installation by reaching down a few logs at a time as you fit them.

FULLY INTERLOCKING LOG CORNERS: These traditionally made log cabins feature interlocking corner logs. Each wall log is precisely machined and notched out to ensure a strong and weatherproof joint. The first log is laid at the bottom and the rest slot into each other, working upwards one log at a time. No screws or nails are required which makes installation easier and also allows for timber movement. The finished corner assembly is not only immensely strong but also weatherproof and draughtproof. If possible cabins with interlocking logs should be treated after assembly. Treating the logs on site before fitting requires considerable care. If swollen the precision milled joints may not slot together.

MADE TO MEASURE: These log garages are supplied as a single room with double hinged doors. You can add a personnel door and joinery windows to suit your individual requirements. These doors and windows can be positioned wherever you want.

PRESSURE TREATED FOUNDATION BEAMS: Substantial foundation beams are laid on the base to support the walls. This ensures that the wall logs are not in contact with the ground. The foundation beams are pressure treated for durability. Pressure treatment is a lifetime preservative treatment. The preservative is forced into the timber under pressure in a vacuum and penetrates below the surface. All other treatments apply a coat of stain to the surface of the timber only. With pressure impregnated timber, the chemicals are permanently fixed in the wood. Tanalith E is the most popular preservative used so pressure treated wood is often described as tanalised. With the foundation beams this log cabin can be built without a floor if required.

DECORATIVE FELT TILES: Mineral coated bitumen felt tiles are an attractive and durable roofing material which is far more hardwearing than standard roofing felt. Traditionally used for small buildings only in the UK, felt tiles are used much more in Scandinavia and North America where they are used widely in general housebuilding. The sophisticated design features a strip of almost dry bitumen adhesive. Over time each tile sticks to the tile below for improved waterproofing and windproofing. All fixings are covered by the next row of felt tiles, partly to ensure a neat appearance with concealed fixings but mainly to protect the fixing holes from any possible moisture. Mineral felt tiles are made using asphalt with a bitumen binder and an external covering of durable and attractive natural stone chips. Mineral felt tiles are often described as felt shingles because the design resembles traditional cedar shingles.

SIZES - LENGTH AND WIDTH: Sizes are sometimes rounded to the nearest nominal size for ease of reading but the correct external wall sizes are listed alongside the price. The first dimension listed is the width and the second dimension is the length. The width refers to the angled gable walls at the front and rear. The length refers to the side walls. The sizes listed are the external wall sizes. These sizes do not include the roof overhang. All sizes are approximate.